Support for Prototype, Single and Mass Production

Support for Prototype production along with development

Our company has been working on developments for prototype production. While providing prototype support from the planning phase, we consider having a balance between the quality of product, cost and delivery, and therefore provide optimized support in manufacturing.

Further, we also provide modified and revised prototypes from cutting works, die cast to die press works, and also proactively provide prototype support for achieving stable quality of products at a low cost by introducing fine press work during mass production.

Mass Production System which Optimizes Quality of Product, Delivery and Cost

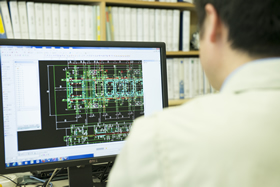

We have accumulated various know how of the optimal quantitative press work by carrying out integrated in-house production for extensive volumes of press work for processes from prototype to small lot, medium lot and mass production.

Especially, from the initial prototyping the products and dies are designed in anticipation of mass production. By considering the quantity, cost and delivery to secure optimal manufacturing at the time of mass manufacture, we are able to secure a stable quality product, as well as provide adequate quality at an adequate price.

Further, our company has achieved highly efficient production and low cost by performing simultaneous multipoint welding which is a process original to our company, wherein the tapping within the die as well as the punching and shaving work are carried out in one process.